Info

Phone

Mail

Address

P.I. 01338800384

Recipient code: BA6ET11

Via F. Luigi Ferrari 24/C

Ferrara

44122

Italy

Studio V.M. S.r.l. ©

We want people to have fun safely!!

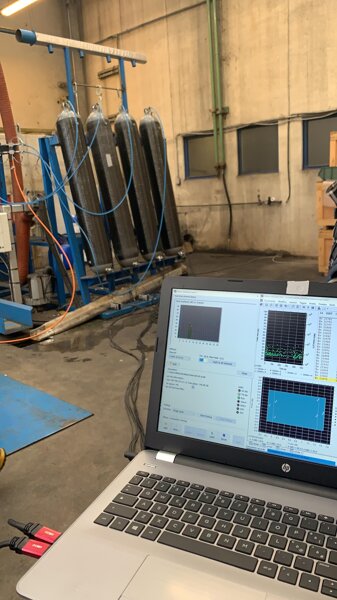

ACOUSTIC EMISSION TESTING (EA)

Acoustic emission testing is carried out to verify the reliability status of both welded and non-welded structures. It is applied to storage tank bottoms, process piping, pressure equipment in service, and newly constructed equipment. The energy released by discontinuities is detected by sensors which, through triangulation algorithms, provide the locations, facilitating ultrasonic verification of the affected areas.

The acoustic emission test is applied to the monitoring of the storage tank bottom. This technique allows verification of the corrosion status and the degree of reliability of the bottom, without emptying the tank.

The largest oil company uses this technique in combination with the measurement of the roof and shell thickness to define the residual life of the tank according to API 653.

Studio V.M. is a leader in Italy for these specialties and the number of cylinders inspected as of July 20 is 944.

The examination is carried out in combination with a pressure test after construction or during the periodic inspection. This test allows verification of whether the component subjected to stress due to the pressure test can withstand the pressure limit value without releasing energy.

This test is also the best control to prevent collapse during the pressure test.

Info

Phone

Mail

Address

P.I. 01338800384

Recipient code: BA6ET11

Via F. Luigi Ferrari 24/C

Ferrara

44122

Italy

Studio V.M. S.r.l. ©